Large Swing Taper Linear Cutting Machine Tool

Machine Type: Wire EDM

Condition: New

CNC or not: CNC

Model: DK77 With Large Swing Taper

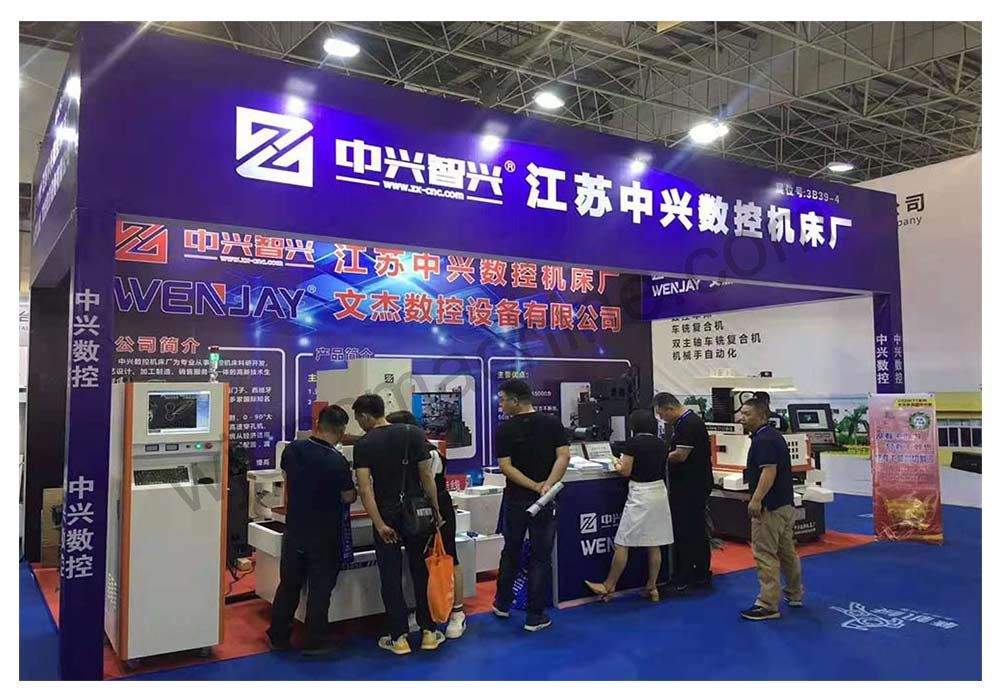

Brand: WENJAY

Place of Origin: Jiangsu, China

Certification: ISO9001:2008, CE

Payment: TT L/C

Function: Single Cut, Wire Cut

MOQ: 1 SET

Product Description

INTRODUCTION

Wenjie's big-tapered linear cutting machine tool is characterized by large stroke, high speed, high precision, high degree of automation, heavy duty and strong specialty, and it is at the leading level at home and abroad, so that it is widely used in aerospace, aviation, military and other fields. Wenjie CNC big-tapered linear cutting machine tool has a good taste, high quality, super stability and low price!

MAIN FEATURE

1. It integrates the traditional VC taper structure composed of the upper plate, medium plate and bottom plate into a plate equipped with Type II guideway, which reduces the parts and simplifies the structure. More importantly, it installs the traditional U-shaped guideway and V-shaped guideway on the same plane, which makes it easy to ensure its vertical accuracy and greatly reduces the difficulty in machining and assembly.

2. It changes the traditional layered suspended structure composed of cantilever, top plate, lower plate, bottom plate and upper arm to the supporting structure, and optimizes the mechanical properties, which have a positive impact especially on maintaining the precision of the guideway pair in the direction of UV.

3. Pendulum shaft link mechanism is one of the decisive factors affecting the machining precision of large taper, while the unique precise pendulum shaft link mechanism is the guarantee of big-tapered cutting precision.

4. The UV driving mechanism adopts the high-grade linear guideway of Taiwan HIWIN, precision ball screw and angular contact bearing structure to improve driving stability and accuracy.

5. The dovetailed sliding block lifting structure is characterized by force balance and smooth guide, stable adjustment of guide frame interval, convenient operation and strong rigidity.

TECHNICAL DATA

Tager Angle: 0~90°

| Type | unit | DK7740 | DK7750 | DK7763 | DK7780 | DK7780F |

| Worktable Size (W*L) | mm | 460×680 | 564×900 | 700×1060 | 850×1340 | 900×1500 |

| X,Y-axis trip(Y×X) | mm | 400×500 | 500×630 | 630×800 | 800×1000 | 800×1200 |

| U,V-axis trip(U×V) | mm | 320×320 | 320×320 | 320×320 | 370×370 | 370×370 |

| Max load weight | kg | 500 | 800 | 1100 | 1500 | 2000 |

| Max linear cutting thickness | mm | 400 | 500 | 500 | 700 | 700 |

| Machined taper/work piece thickness | 60°/200mm Taper model of swing guide Wheel | |||||

| Z-axis elevation mode | electric elevation | |||||

| Type of guide track | Slide guide | |||||

| Electrode wire diameter range | mm | Ф0.10~0.20mm | ||||

| Wire speed | m/sec | 1~11.4m/sec 7 frequency conversion adjustable | ||||

| Machining accuracy | mm | ≤0.015 | ||||

| Max cutting efficiency | mm²/min | ≥120 | ||||

| Optimum surface roughness | um | Ra≤3.0 | ||||

| Control mode | X, Y, U, V stepper motor | |||||

| Number of control axis | Four-axis linkage | |||||

| Min instruction unit | mm | 0.001 | ||||

| Power supply | Three-phase four-wire 380VAC/50HZ | |||||

| Max operating current | A | 10 | ||||

| Machine tool power consumption | kw | ≤2 | ||||

| Working fluid | DX-1 DX-4 Nanguang-1 | |||||

| Working fluid tank volume | L | 55 | ||||

| Work liquid filtrate way | Strainer | |||||

| Host weight | kg | 1400 | 2200 | 3000 | 5000 | 6000 |

| Host outline size | mm | 1700×1400×1400 | 2100×1700×1740 | 2400×2250×1650 | 3000×2500×2000 | 3000×2700×2200 |

PACKAGE

1. Shrunck plastic film + plywood case

2. Shrunck plastic film + steel pallet

3. Customerized package

DELIVERY TIME

7 days after order confirmation

WARRANTY

One year

During warranty period, we can provide free parts and components that are not damaged due to improper operation (consumables are excluded). Out of warranty period, we will supply our best service to you as usual, if you have any question.

1. Offer technical support online service.

2. Technical files service & on-site training service provided.

3. Offer machine operation video.

4. Spare parts replacement and repair service provided.

5. All questions will be replied within 12 hours.

FAQ

Q: Are you a manufacturer or trading company?

A: We are the professional manufacturer of cnc wire cut edm machine, which have been in the industry for 20 years more. All the casting and metal plates are made by ourselves.

Q: Can you provide training and maintenance?

A: Yes. In order to make your production more efficient, before the delivery, you can send someone to my company for professional operation training.

Q: What information will you need to make the proposal?

A: Worktable size, worktable travel, surface finish, machining accuracy, and your special requirement.

OUR FACTORY

OUR EXHIBITION

We have strong production capacity, fast delivery time, and professional technical support.

What we offer is on best price, and with best quality.

We focus on product innovation, and respect of client needs, culture, identity, objectives.