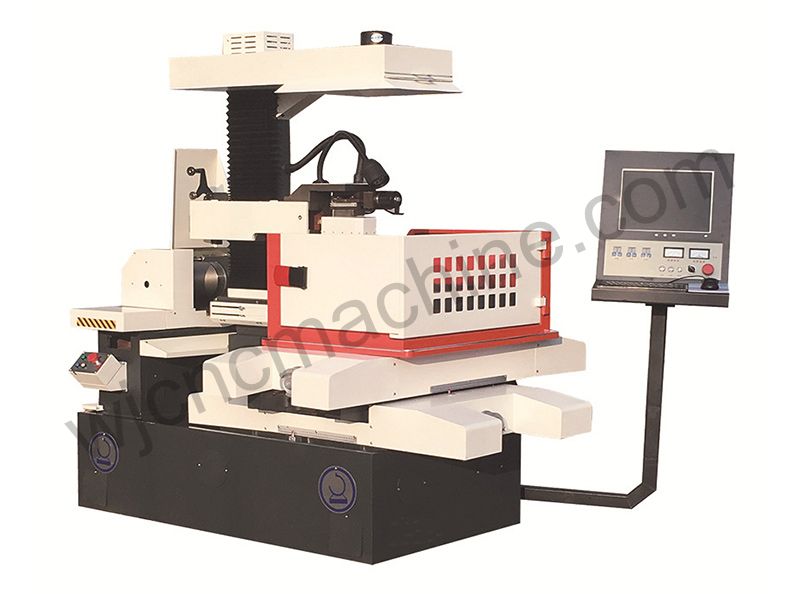

SUPER LARGE HIGH SPEED WEDM

Machine Type: Wire EDM

Condition: New

CNC or not: CNC

Model: GSDK77

Brand: WENJAY

Place of Origin: Jiangsu, China

Certification: ISO9001:2008, CE

Payment: TT L/C

Function: Wire cut, Single cut, High speed

Cutting Speed: 15,000mm2/hour

MOQ: 1 SET

Product Description

Super Large High Speed Wire Cut EDM Machine

With the continuous increase in the technical cost of wire cut EDM machine, precision wire cut EDM machine has become an urgent problem to reduce production costs and improve performance. At the same time, the double wire cutting technology produced by wire cutting machines has become A powerful production tool and its application.

For many enterprises with a certain scale, the rapid development of the market makes it necessary to find ways to reduce production costs on the one hand, and on the other hand to do everything possible to shorten the processing time. When they are combined with costs at the same time, another partner-machine tool manufacturing enterprise is working hard to help them improve product quality, output, and product economy. Take the manufacturer of wire cut EDM machine as an example, they are taking a variety of methods to reduce the user's operating costs. These are mainly reflected in the following aspects:

1. Improve the efficiency of the pulse power supply of the wire cut EDM machine and reduce the overall energy consumption of the equipment.

2. Emphasize to reduce the running speed of wire-cut electrode wire and develop new technology of electric discharge machining.

3. Improve the machining accuracy of rough machining and reduce the number of trimming.

4. Improve the processing speed and processing precision of thin wires (below φ0.1mm) EDM wire cutting brass electrode wires, because, in some application fields, they can replace thick wires (above φ0.2mm) for processing.

The above method is very effective for improving processing efficiency. In addition, the EDM wire cutting machine can also be regarded as a machining center, which realizes the automatic interchange of rough machining and finishing electrode wires, which can also achieve the purpose of improving efficiency and reducing costs.

Performance of wire cut EDM machine:

1. Four-axis linkage, wire breaking protection.

2. Efficiency: Cutting efficiency is 15,000 m2 per hour.

3. Low consumption: 600,000-800,000 m2/one litre of cutting fluid.

4. Low noise, reasonable price.

5. Easy to maintain.

6. Especially suitable for mould processing.

Features of wire cut EDM machine

Environmental protection:

(1) It is equipped with automatic demist device, which eliminates the free oil, water, and gas in the air and greatly improves the operating environment;

(2) cutting fluid adopts the exclusive formula, which requires no replacement for a lifetime. When the concentration is low, it is necessary to add cutting fluid only, rather than dumping, which is free from contamination. ★It adopts the integrated computer control, which integrates computer, high-frequency power supply, driving power and electric equipment for machine tools so that it is attractive, environmentally-friendly, easy to operate and reduces the floor area.

Wire Cut EDM Machine Technical Data

Taper Angle: 0~12°

| Type | GSDK7780 | GSDK7780F | GSDK77100 | GSDK77100B |

| Worktable Size (mm) | 850×1340 | 900×1500 | 1100×1500 | 1100×1700 |

| X, Y-axis trip(mm) | 800×1000 | 800×1200 | 1000×1200 | 1000×1400 |

| U, V-axis trip(mm) | 70×70 | |||

| Max load weight (KG) | 1500 | 2600 | 3000 | 3400 |

| Max linear cutting thickness (mm) | 800 | 800 | 1000 | 1000 |

| Machined taper/workpiece thickness | 12°/80mm | |||

| Z-axis elevation mode | Manual/Electric Elevation | |||

| Type of guide track | Slide guide | |||

| Electrode wire diameter range (mm) | Ф0.15~0.20mm | |||

| Wire-speed (m/sec) | 1~11.4m/sec 7 frequency conversion adjustable | |||

| Machining accuracy (mm) | ≤0.015 | |||

| Max cutting efficiency(mm²/min) | ≥250 | |||

| Optimum surface roughness (µm) | Ra≤2.5 | |||

| Control mode | X, Y, U, V stepper motor | |||

| Number of control axis | Four-axis linkage | |||

| Min instruction unit (mm) | 0.001 | |||

| Power supply | 380V/50HZ 3P4W | |||

| Max operating current (A) | 12 | |||

| Machine tool power consumption | <2(KW) | |||

| Working fluid | Special for Wenjie (self-made), equipped with a concentration meter | |||

| Working fluid tank volume (L) | 55 | |||

| Work liquid filtrate way | Strainer, magnetic plate | |||

| Weight (KG) | 3800 | 4600 | 5000 | 5500 |

| Size (m) | 3×2.5×2 | 3×2.7×2.2 | 3×2.8×2.5 | 3.28×2.8×2.5 |

Taper Angle: 0~12°

| Type | GSDK77120 | GSDK77120B | GSDK77120F | GSDK77160 |

| Worktable Size (mm) | 1900*1310 | 2100*1310 | 2300*1310 | 2300*1670 |

| X, Y-axis trip(mm) | 1200*1600 | 1200*1800 | 1200*2000 | 1600*2000 |

| U, V-axis trip(mm) | 70×70 | |||

| Max load weight (KG) | 4500 | 5500 | 6000 | 8000 |

| Max linear cutting thickness (mm) | 1000 | 1000mm(930) | 1000mm(930) | 1000mm(930) |

| Machined taper/workpiece thickness | 12°/80mm | |||

| Z-axis elevation mode | Manual/Electric Elevation | |||

| Type of guide track | Slide guide | |||

| Electrode wire diameter range (mm) | Ф0.15~0.20mm | |||

| Wire-speed (m/sec) | 1~11.4m/sec 7 frequency conversion adjustable | |||

| Machining accuracy (mm) | ≤0.015 | |||

| Max cutting efficiency(mm²/min) | ≥250 | |||

| Optimum surface roughness (µm) | Ra≤2.5 | |||

| Control mode | X, Y, U, V stepper motor | |||

| Number of control axis | Four-axis linkage | |||

| Min instruction unit (mm) | 0.001 | |||

| Power supply | 380V/50HZ 3P4W | |||

| Max operating current (A) | 12 | |||

| Machine tool power consumption | <2(KW) | |||

| Working fluid | Special for Wenjie (self-made), equipped with a concentration meter | |||

| Working fluid tank volume (L) | 55 | |||

| Work liquid filtrate way | Strainer, magnetic plate | |||

| Weight (KG) | 8000 | 9000 | 10000 | 12000 |

| Size (m) | 4*3.1*2.8 | 4*3.3*2.8 | 4*3.5*2.8 | 4.5×3.5×2.8 |

Wire cut EDM machine details:

Package of wire cut EDM machine

1. Shrunk plastic film + plywood case

2. Shrunk plastic film + steel pallet

3. Customerized package

Wire cut EDM machine delivery time:

15 days after order confirmation

WARRANTY: One year

During the warranty period, we can provide free parts and components that are not damaged due to improper operation (consumables are excluded). Out of warranty period, we will supply our best service to you as usual, if you have any questions.

1. Offer technical support online service.

2. Technical files service & on-site training service provided.

3. Offer a machine operation video.

4. Spare parts replacement and repair service provided.

5. All questions will be replied within 12 hours.

FAQ

Q: Are you a manufacturer or trading company?

A: We are the professional manufacturer of CNC wire cut EDM machine, which have been in the industry for 20 years more. All the casting and metal plates are made by ourselves.

Q: Can you provide training and maintenance?

A: Yes. In order to make your production more efficient, before the delivery, you can send someone to my company for professional operation training.

Q: What information will you need to make the proposal?

A: Worktable size, worktable travel, surface finish, machining accuracy, and your special requirement.

OUR FACTORY

OUR EXHIBITION

1. We have strong production capacity, fast delivery time, and professional technical support.

2. What we offer is at the best price, and with the best quality.

3. We focus on wire cut EDM machine innovation, and respect of client needs culture, identity, objectives.